Mining Surveys

For over a decade, True North Surveys team has specialized in the mining survey sector in the Canadian arctic and sub-Arctic region. We offer surveying services throughout the project lifecycle including exploration, construction, production, operation, and reclamation.

We excel in providing survey solutions for both underground and surface mining operations. We understand the importance of timely results in the mining industry. Our streamlined processes and workflows minimize downtime and maximize productivity.

Our team of skilled surveyors combines technical expertise with a deep understanding of mining dynamics. Whether you are embarking on a greenfield project or seeking to enhance productivity in existing operations, we tailor our surveying services to meet your specific needs.

TNS offers a variety of geomatics solutions for mines including:

- Open Pit and Underground mining surveys

- Surface and underground high precision control surveys

- Blast pattern layout and design

- Aerial mapping and orthophoto of site

- Drill collar surveys

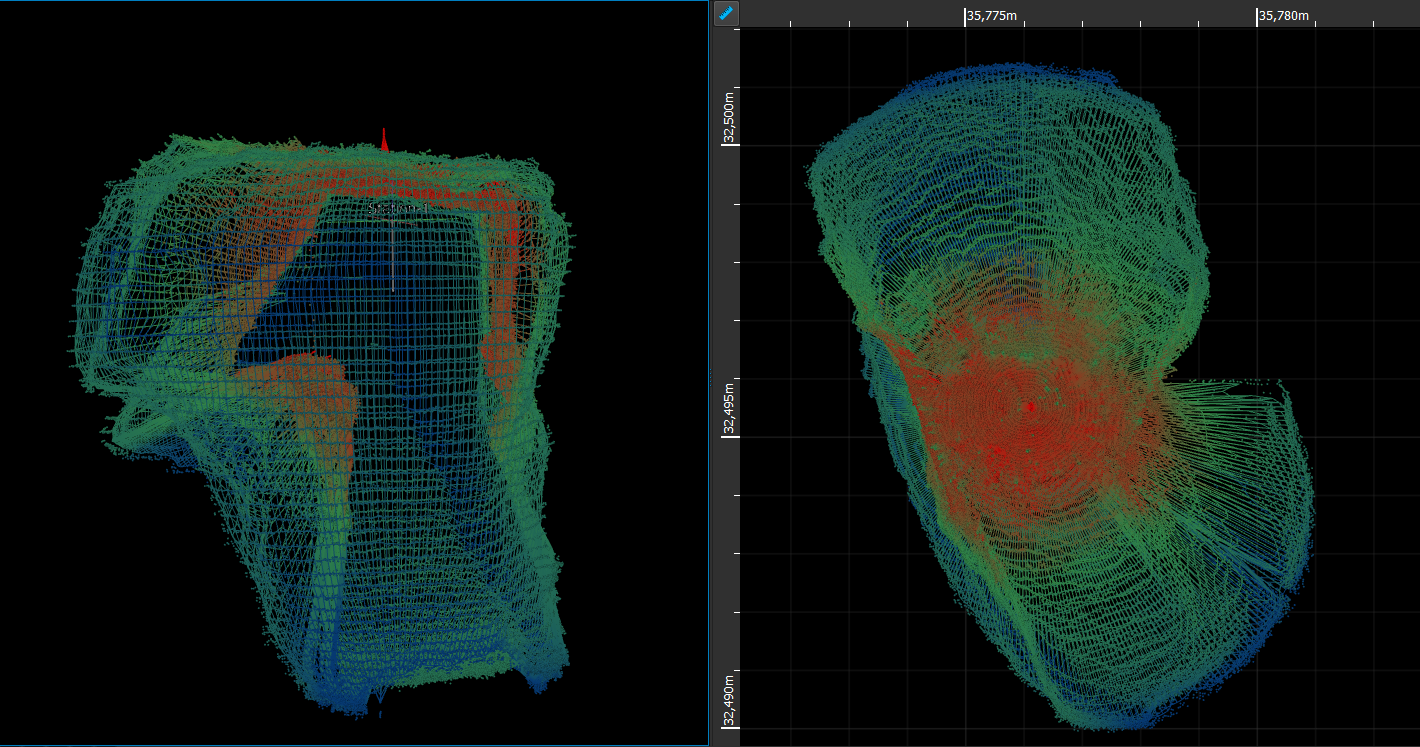

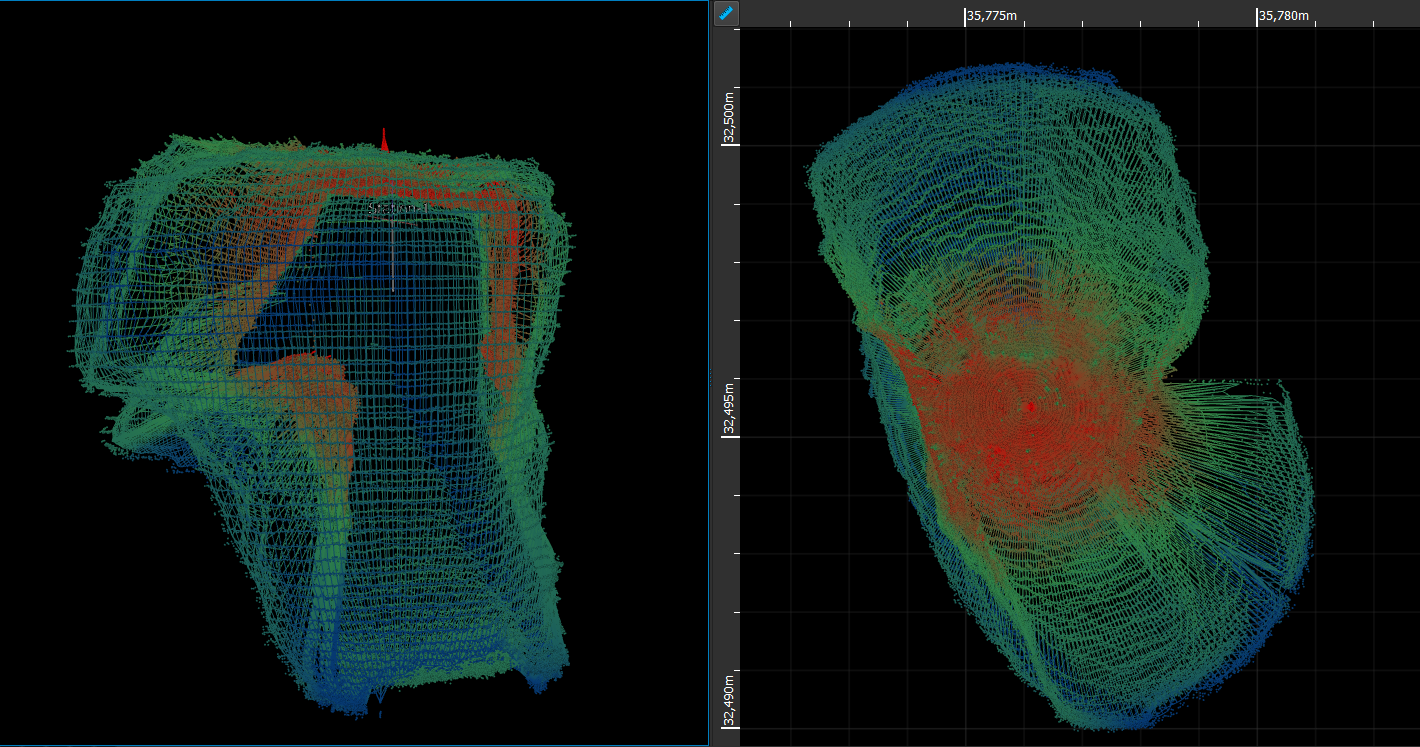

- 3D Scanning

- Pre engineering surveys

- Construction surveys

- Mill and conveyor layout

- Dam deformations surveys

- UAV drone survey for tailings

- Bathymetric surveys

- Earthworks volumes for quantity payments

- Road reconnaissance surveys

- Regional geochemical sediment surveys

- Quality control surveys

- Powerline and substation layout

Our mining survey specialization extends to drilling survey services which includes : precise drill alignment, downhole surveys, directional drilling and cavity monitoring scanning.